Early Days and Business Innovations

Michael Howell’s journey in the world of engineering began over 15 years ago. Sparked by a desire to innovate and grow, he initially worked with various structural and mechanical systems, constantly seeking opportunities to expand his knowledge and capabilities. His early career saw him taking on diverse projects, from vertical constructions to platforms, always with an eye for something bigger and better.

During this period, Michael realized the importance of having the right tools and technologies at his disposal to enhance productivity and accuracy. This realization became a driving force behind the establishment of Arrow Engineering, a company he created with a goal of not only providing designs that met industry standards but also endeavored to set new ones through innovative practices and advanced software solutions.

From One-Man Band to a Growing Team

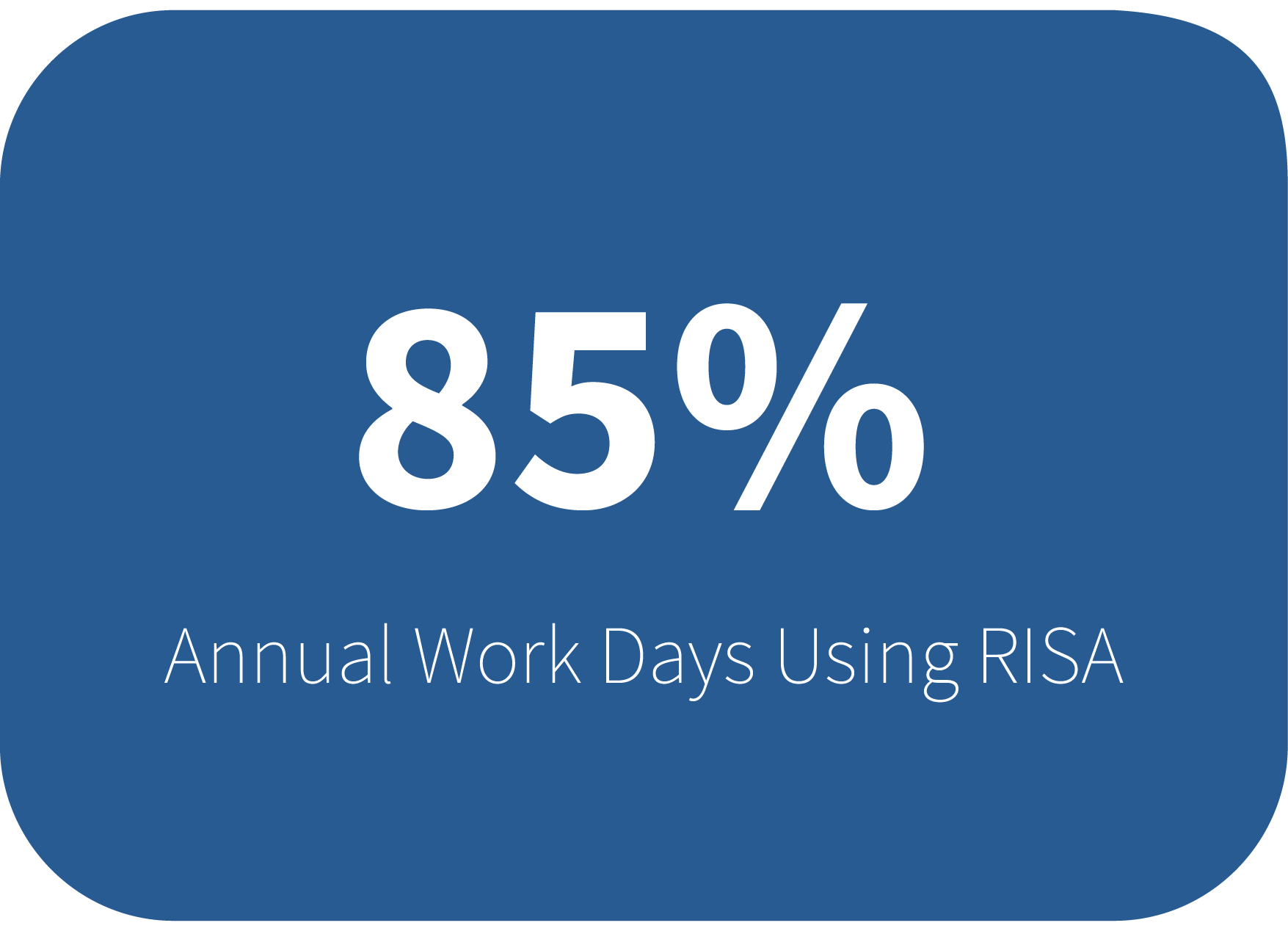

When Michael founded Arrow Engineering, he was a one-man operation, working out of a small office while juggling a variety of roles from project management and finance, to IT and software license management. As the firm began to grow, the integration of RISA’s structural engineering software suite began to play a critical role in project delivery. RISA’s advanced tools streamlined project workflows, increased accuracy in structural analysis, and enabled better collaboration among team members.

Managing the financial aspects of the business, Michael ensured that the firm could afford the necessary software licenses and other operational costs without compromising on quality. The strategic implementation of RISA not only improved project management efficiency but also optimized financial planning. By automating complex calculations and reducing manual errors, RISA allowed the firm to take on more ambitious projects, ultimately driving growth.

Expanding Capabilities with Integration of RISA

The turning point for Arrow Engineering came when Michael decided to integrate RISA software into their operations. The decision was driven by a project that required extensive steel redesign and connection modifications. RISA-3D proved to be the perfect solution, offering the capabilities needed to tackle the challenges effectively. The successful implementation of RISA in this project not only resolved the structural issues at hand but also demonstrated a significant return on investment and increased profitability.

This improved process marked the beginning of a new era for Arrow Engineering. The ability to handle complex calculations and detailed modeling with ease allowed the company to take on larger and more intricate projects, thus making RISA software a cornerstone of their operations, enabling the team to work more efficiently and accurately.

“RISA’s tools and support have been integral to our growth and ability to take on larger projects. We wouldn't be where we are today without RISA.”

Michael Howell, SE, PE

Owner & Founder of Arrow Engineering

Evolving Software Journey

Arrow Engineering’s software journey has been one of continuous growth and adaptation. Initially, Michael juggled finances and resources to acquire RISA, a testament to his commitment to the company’s long-term vision. The early days were marked by a steep learning curve, but the benefits quickly became evident. The intuitive user interface and robust capabilities of RISA software helped streamline operations and enhance the overall quality of their work.

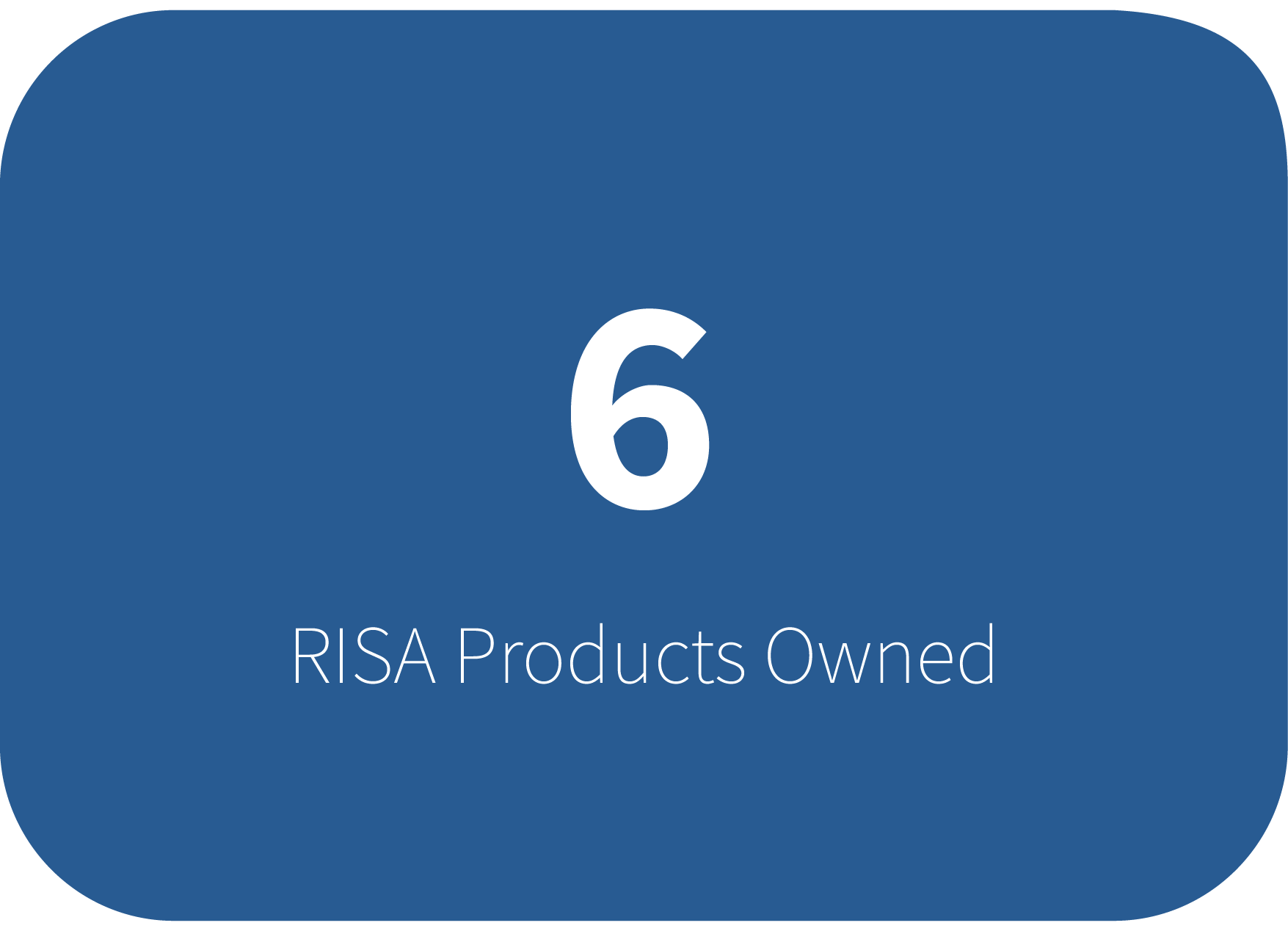

While the journey started with RISA-3D, it was only just the beginning. As the company grew, so did their software arsenal. RISAFloor, RISAFoundation, and RISAConnection became integral parts of their toolkit. Each new software addition brought with it new capabilities, allowing Arrow Engineering to expand their service offerings and take on a wider range of projects.

Advancements with RISA

The continual advancements and improvements implemented by RISA have also been instrumental in Arrow Engineering’s success. One of the standout features has been the ability to perform detailed analyses and generate comprehensive reports, which are crucial for project planning and execution. The software’s ability to handle multiple material types and complex structures has allowed the company to take on projects of varying scales and complexities.

A recent highlight has been a $50 million school project (the firms largest to date), entirely designed using RISA software. This project exemplifies the company’s growth and their ability to handle large-scale projects efficiently. The team at Arrow Engineering, now well-versed in using RISA, managed the project independently, showcasing their expertise and the software’s capabilities.

Looking Ahead: Future Plans

Looking ahead, Michael Howell envisions a future where Arrow Engineering continues to push the boundaries of what’s possible in structural engineering. The company plans to stay at the forefront of technology adoption, continually integrating the latest advancements to enhance their services. There is a strong focus on expanding their reach and taking on more diverse and challenging projects.

The use of RISA software will continue to be a key component of the firm’s strategy, with ongoing developments leveraged by Arrow Engineering to provide customer efficient designs. All of this should allow the company to achieve continued growth, both in terms of project scale and technological prowess, ensuring they remain a leader in the engineering field.

In summary, Michael Howell’s journey with Arrow Engineering is a story of innovation, resilience, and growth. From its early days as a one-man operation, the firm has leveraged cutting-edge technology like RISA software to compete against larger firms and efficiently deliver large-scale projects. The strategic use of RISA has streamlined project management, optimized financial planning, and ensured up-to-date license management, allowing the small firm to punch above its weight. With a solid foundation built on advanced software solutions, Arrow Engineering is well-positioned to tackle future challenges and achieve new heights in the engineering industry.

Growth with RISA

Arrow Engineering By the Numbers